Roman Mining: Industry, Innovation, and Imperial Wealth

Introduction

Table of Contents

Mining played a central role in the economy of ancient Rome, supplying the metals and materials that fueled its currency, armed its legions, and built its cities. From the Iberian silver veins to the tin streams of Britain, the empire’s expansion often followed the lure of mineral wealth. Emperors and generals took pride in conquering regions rich in gold, silver, and iron, knowing these resources would finance their ambitions and display Rome’s dominance over nature. In an age before modern banking, wealth literally came out of the ground, and Roman engineers and laborers toiled to ensure the empire reaped the profits.

The importance of mining extended beyond coins and weaponry. Massive public works like aqueducts and baths depended on lead pipes and iron tools forged from Roman ores. Temples gleamed with gilded roofs and marble inlay thanks to gold and pigment mined in distant provinces. By the 1st century AD, state officials were directly overseeing major mines and funneling their output to Rome. The phrase “all the gold under the earth” became synonymous with imperial fortune. Indeed, mineral wealth was a foundation of Roman might: the treasure of conquered mines filled state coffers, paid soldiers and architects, and reinforced the idea that Rome’s prosperity was divinely ordained. Yet, as the following sections show, this prosperity came from feats of engineering and the labor of those hidden in the empire’s mineshafts.

Types of Minerals and Sites

Precious Metals: Gold and Silver

The red cliffs of Las Médulas in Spain were carved by Roman hydraulic mining. Once the empire’s largest gold mine, Las Médulas’s mountains were literally washed away by torrents of water to extract precious gold. The Romans exploited an astounding variety of minerals across their vast territories. Foremost were precious metals: gold and silver. In northwestern Spain, Las Médulas became legendary as the empire’s largest open-cast gold mine, where streams were diverted to pulverize entire hillsides in a technique called ruina montium (“wrecking of mountains”). This hydraulic assault yielded enormous quantities of gold for the imperial treasury.

Further south in Iberia, rich silver deposits were the prize of conquest. The province of Hispania (modern Spain) boasted silver mines that had once funded Carthage and now filled Roman mints. Around Carthago Nova (Cartagena), tens of thousands of enslaved workers labored in silver and lead mines, producing bullion that was shipped back to Rome for coinage. These Spanish mines were so productive that their output fueled Rome’s currency for centuries and became a strategic asset – any threat to Iberia’s mines was a threat to imperial finance.

Base Metals: Copper and Tin

Beyond the precious metals, Rome hungered for base metals essential to daily life and war. Copper and tin were critical for making bronze (used in coins, weapons, and tools), and the empire sought them far and wide.

In Britain, newly conquered in the 1st century AD, the Romans found abundant tin in Cornwall and copper in highland Wales and along the English borders. Within a generation, Britain became one of the top metal-producing regions of the empire, exporting ingots of tin and copper to continental workshops.

At the same time, the island of Cyprus in the eastern Mediterranean – whose very name gives us the Latin word for copper (cuprum, from aes Cyprium, “metal of Cyprus”) – remained a major source of copper under Roman control. Mediterranean Cyprus had been famed for copper since the Bronze Age, and under Rome it continued to ship tons of ore and refined copper for use across the empire.

Iron: The Soldier’s Metal

The metal that armed Rome’s soldiers was one of the most common: iron. Iron ore was widespread, but certain regions produced superior quality.

The province of Noricum (in the eastern Alps) was celebrated for its high-grade iron, which when properly worked produced Noric steel – prized for swords and armor. After Noricum was absorbed into the empire, its iron mines and skilled forges supplied the legions with steel blades “harder than iron from other lands,” according to Roman poets.

Similarly, Gaul (modern France and Belgium) and parts of Germania had large ironworking centers, often located near forests (for charcoal fuel) and iron-rich bogs or hills. Roman mines in Gaul and the Rhineland yielded the iron for countless nails, tools, and weapons, making this unglamorous metal a backbone of both the military and civilian economy.

Byproducts and Utility: Lead

Some materials were byproducts of other mining yet proved extremely useful. Lead was one such resource – often found alongside silver in the form of lead ore (galena). Roman miners would smelt galena for its silver content, then cast the leftover lead into ingots.

Lead had a multitude of uses in Roman life: it was the metal of water pipes, roof sheets, coffins, and even sling bullets. By the 70s AD, Britain’s lead mines (for example in the Mendip Hills and Wales) were so productive that they outpaced older mines in Spain, and Roman Britain became the empire’s leading lead exporter.

Large rectangular lead ingots stamped with the mark of imperial agents or legion numbers have been found, some shipped as far as Italy, evidence of an organized trade. Lead’s heaviness made sea transport preferable, so British lead went by ship to Gaul and Rome’s harbors. Though common and cheap, lead was in constant demand – so much so that the emperors closely monitored its production to prevent fraud or shortages.

Non-Metallic Minerals: Salt, Mercury, and Gemstones

Not all Roman mining was for metals. The empire also heavily exploited salt and other minerals. Salt (sal in Latin) was crucial for food preservation and seasoning, and Roman engineers developed both salt mines and coastal salt pans.

In places like the Iberian Peninsula and North Africa, workers mined rock salt from hills, while along the Mediterranean coasts and around the Italian peninsula, seawater was evaporated in shallow ponds to collect salt crystals. The importance of salt is reflected in the Via Salaria (“Salt Road”) leading to Rome and even the word “salary,” which some say comes from soldiers’ salt rations.

Another valued mineral was cinnabar, the ore of mercury. The brightest source was Almadén in Spain, home to the ancient world’s richest mercury deposit. Romans mined cinnabar both as a red pigment (vermilion) and to extract liquid mercury. Mercury was used in gilding and refining gold, but its extraction was dreadfully toxic – enslaved miners in the mercury mines were effectively condemned to short, poisoned lives, a fact not lost on Roman writers.

Finally, the Romans adored gemstones and sought them within their realms. In Egypt’s eastern deserts, they took over the “Cleopatra’s Mines” of emerald after annexing Egypt, greatly increasing output of these green gems. Amethyst (purple quartz) was also mined in the Eastern Desert, and garnet, jasper, and other semi-precious stones came from places like Britain and Germania.

Truly precious stones like diamonds or rubies were imported from beyond Rome’s borders (India or Sri Lanka), as were pearls from the Red Sea and Persian Gulf. Nonetheless, the quest for gemstones led Romans to establish mines in remote deserts and mountains, highlighting that nearly every glittering or useful substance in the ground was, at some point, extracted under Roman authority.

Each province contributed its geological gifts: gold from Spain and Dacia, tin from Britain, iron from the Danube and Gaul, marbles from Greece and Asia Minor (for sculpture and architecture), and so on. Together, these diverse resources formed a vast imperial mining network.

Techniques and Tools

Mining on the scale of the Roman Empire required remarkable technical ingenuity. Roman miners employed a range of methods to dig out ores, from simple surface collection to deep, complex underground operations.

Opencast Mining and Surface Techniques

In regions where ore lay near the surface, opencast (surface) mining was common. This involved removing soil and rock to expose the mineral veins. At sites like Las Médulas (Spain) and Dolaucothi (Britain), opencast techniques were taken to extreme lengths.

One dramatic method was hushing, which harnessed water to strip away overburden. Engineers built aqueducts or reservoirs above a deposit, then suddenly released water to wash soil and loose rock downhill, laying bare the veins of gold or tin beneath. Once exposed, the rock could be attacked with picks or wedges.

Another opencast technique was fire-setting – particularly useful in hard rock. Miners would build intense wood fires against a rock face and then douse the hot rock with water or vinegar, causing it to crack from thermal shock. The fractured stone could then be pried apart with iron tools. Fire-setting was laborious and smoky, but it was one of the only ways ancient miners could break through tough ore-bearing rock before the advent of explosives.

Underground Mining Methods

After surface deposits were exhausted, the Romans pursued ore underground via shafts and tunnels. They dug vertical shafts deep into the earth and then ran horizontal galleries or adits following the ore seams.

In mining regions like the Iberian mountains or the Black Forest, Roman shafts reached impressive depths for the time – sometimes over 100 meters down. Without modern drills, these shafts had to be chiseled by hand through rock, illuminated only by flickering oil lamps.

The miners used iron picks, hammers, and chisels to carve their way, inch by inch. Wooden beams were installed to support tunnels and prevent cave-ins, although collapses remained a constant danger. Ventilation was another challenge; deep underground, miners risked suffocation from lack of airflow or the buildup of noxious gases.

Roman engineers addressed this by digging multiple shafts to create airflow or by using shafts of different heights to induce convection currents. In some cases, they also lit fires at the bottom of one shaft to draw stale air up and force fresh air down another shaft – a primitive but effective ventilation system. Pliny the Elder, a Roman scholar, described how miners “do not see daylight for months” and measure their shifts by lamp fuel, a testament to the length of underground work shifts and how critical lamps were in those perpetually dark galleries.

Water Management and Machinery

Romans were adept at using water management and machinery to assist their mining operations. One major problem in deep mines is groundwater flooding. To counter this, Roman engineers devised pumping and drainage systems that were cutting-edge for their time.

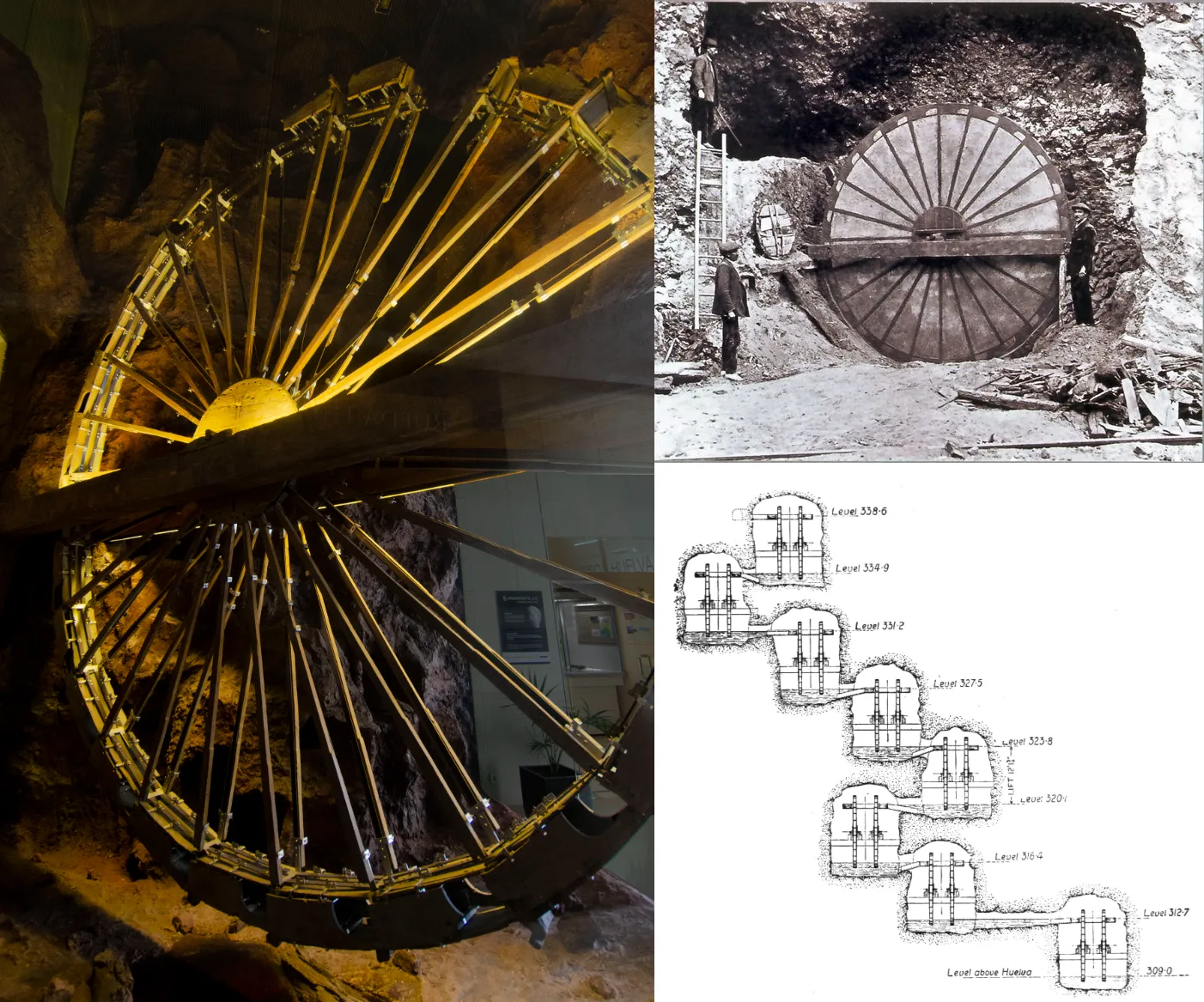

A common device was the water wheel pump, a kind of drainage wheel. These wooden wheels, fitted with buckets or paddles, were installed in mine shafts to lift water out of deep tunnels. Sets of wheels could be stacked in stages: the lowest wheel scooped water from a sump at the bottom, emptied it into a trough higher up, where the next wheel lifted it further, and so on, cascading the water upwards and eventually out of the mine.

Some of these installations used up to sixteen successive water wheels to raise water nearly 80 meters to the surface. The wheels were turned either by human power (slaves or workers treading on them or cranking) or by the flow of water itself if situated in a stream.

Archaeologists have found remains of such Roman drainage wheels in the Rio Tinto mines of Spain, including wooden fragments that survived waterlogging. Impressively, one waterwheel fragment from Rio Tinto shows sophisticated joinery and was over four meters in diameter.

Diagram of a Roman mine drainage wheel (side view and plan). This wooden wheel, found in a Spanish mine, was part of a sequence used to lift water out of deep shafts. Roman engineers linked multiple wheels to pump water up to the surface, an ingenious solution to flooded tunnels.

Beyond wheels, the Romans also employed the Archimedean screw (a corkscrew-like pump) in some mines to raise water. The Archimedean screw, invented in the Hellenistic period, consists of a helical blade inside a tube; when turned, it lifts water upward.

Evidence suggests the Romans knew of and occasionally used such screws in mining or irrigation, though the more common solution was the noria (water wheel). In certain hilly mining areas, they even built inverted siphons and drainage adits to channel water out by gravity.

At Dolaucothi in Wales, for example, a long drainage adit was cut through solid rock to allow water to escape from deep workings – essentially a horizontal tunnel draining to the hillside, so groundwater could flow out naturally.

Ore Processing and Sluicing

Another aspect of Roman mining was sluicing and washing of ores. After raw ore-bearing rock was extracted, it needed processing to separate the metal.

Romans directed flowing water over crushed ore on sloping wooden tables or channels. Heavy metals like gold would settle on riffles (raised bars) in these sluice boards, while lighter sand and mud washed away. This gravity separation was crucial for gold and tin extraction.

Pliny described how gold particles, freed from mountain debris, were collected by washing over riffle tables. In some Spanish gold mines, purpose-built reservoirs released water in controlled floods to carry off lighter waste and leave heavier gold-bearing material behind – a technique known as sluicing.

The scale of waterworks for mining was enormous: Las Médulas had at least seven aqueducts bringing water from distant mountains for its hydraulic mining operations, and complex networks of canals and reservoirs are found at many mining sites (the remains of these channels are often still visible today).

Tools and Labor

In terms of tools, Roman miners were well equipped by the standards of antiquity. They used iron picks and mattocks to break rock, iron shovels to remove debris, and wedges driven by hammers to split larger boulders.

Where needed, they drilled small holes in rock using iron bits and pounded in wooden pegs, which they then wetted so the wood would swell and crack the rock (another clever low-tech cracking method).

For hauling ore and waste, they employed wicker baskets, leather sacks, and wheelbarrows. In cramped tunnels, much of the hauling was done by human muscle – often young boys or women were tasked with carrying heavy baskets of ore to the surface via ladders.

Lighting was provided by simple clay lamps filled with olive oil, clipped to niches in the tunnel walls or carried by hand; traces of soot in mine galleries testify to the countless hours lamps burned in those passages. Even the illumination posed risks: the lamps consumed precious oxygen and could cause blackening smoke in poorly ventilated shafts.

Legacy of Roman Mining Technology

Despite these hardships, Roman mining technology was effective enough to achieve prodigious outputs. Their combination of hydraulic power, fire-setting, sturdy iron tools, and mechanical pumps allowed them to extract ores on an industrial scale for the first time in Europe’s history.

Writers of the day marveled at feats like the ruina montium at Las Médulas, likening it to the work of mythic giants. Indeed, by employing natural forces (water and fire) and mechanical invention (wheels and screws), the Romans could tackle orebodies that previous peoples had barely scratched.

The techniques and tools developed or refined by Roman engineers set a standard in mining that would not be significantly exceeded until the modern Industrial Revolution.

Labor and Workforce

Mining in Roman times was gritty, perilous work, and those who descended into the earth to claw out its riches were often society’s most vulnerable. The Roman mining workforce was a mix of enslaved people, convicted criminals, and sometimes free laborers, including specialists and local villagers drafted for seasonal work.

Condemned Workers and Enslaved Labor

At the bottom of the hierarchy were slaves and damnati ad metalla – literally “those condemned to the mines.” Under Roman law, serious criminals (like murderers, rebels, or deserting soldiers) could be sentenced to the mines as a form of living death. These convicts, as well as prisoners of war, were handed over to state mines or private contractors to perform the most excruciating tasks.

Conditions for them were notoriously brutal. Ancient commentators noted that being sent to certain Spanish or Sardinian mines was a fate few survived. Diodorus Siculus, a Greek historian, described how in Spanish silver mines “40,000 slaves labored day and night, dying in droves from the incessant toil.” Shackled in chains, beaten by overseers, and given minimal food, these condemned workers had virtually no chance of freedom; they were worked until they collapsed and died, their bodies often discarded in the mine debris rather than formally buried.

Enslaved Labor in Private Mines

Enslaved people not under judicial sentence also formed a major part of the labor force, especially in privately run mines. Wealthy Roman mine owners or lessees would purchase large numbers of slaves to use in extraction and processing. These enslaved miners included men, women, and even children.

They lived in makeshift barracks or mining camps near the work sites, under the watch of taskmasters. The daily regimen was relentless: a dawn wake-up, a ration of coarse bread and water (sometimes with a sip of sour wine called posca to dull thirst and pain), then hours spent in dark tunnels swinging picks or hauling loads.

Accounts speak of miners working nearly naked in the stifling heat of deep shafts — one report from a Spanish mine noted a miner only wore a helmet and boots in a 49°C (120°F) underground environment. Injuries were common, from collapsing tunnels, falling rocks, or simply severe exhaustion. Yet there was little mercy: a miner who fell ill or lame might be left to perish since replacement labor was always available from Rome’s constant wars and slave markets.

Free Labor and Skilled Workers

It would be wrong, however, to think all mining labor was coerced. The sheer scale of Roman mining meant that free laborers and skilled workers were also employed, particularly in roles requiring expertise.

For example, at state-run mines, there is evidence that some miners were paid wages (perhaps as a form of incentive or because their skill was valued). Some were likely local freeborn villagers who knew the terrain or had traditional knowledge of panning and prospecting.

Others might be technically “slaves” but given a stipend for skilled tasks like furnace operation or blacksmithing. At the great Rio Tinto mines, records suggest that surface smelting jobs and teaching roles (training new workers) could earn a wage even for slaves.

Roman military veterans or soldiers were at times seconded to work in mines as supervisors or technicians, especially when a new mine was opened in hostile territory. The presence of soldiers also helped guard valuable output and prevent rebellions in the workforce. In one notable case, a fort was established near the Dolaucothi gold mines in Wales, indicating a military oversight of that remote mining operation, likely to safeguard the gold and maintain order among the miners.

Life in Mining Settlements

Life in the mining settlements was harsh and austere. Many mines were in frontier areas or deep mountains and forests, far from the amenities of Roman urban life. The mining camps (often called metalla in Latin) functioned almost like prison camps or remote villages.

At some large mines, the community included not just miners but also support staff: blacksmiths to mend tools, doctors or herbal healers to tend injuries, and even prostitutes and merchants catering to the workers. The Roman administration, especially at imperial mines, provided certain facilities to keep the workforce functional.

Bathhouses, for instance, were built at some mines – not out of luxury, but because a clean, warm bath could soothe aching muscles and possibly prevent disease. One surviving set of regulations (the Vipasca tablets from a mine in Portugal) even specifies that baths must be kept free for the use of miners and the slaves of the mine’s procurator, indicating an official concern for basic hygiene and morale.

The same tablets mention concessions for a barber and a doctor at the mining site, implying that grooming and medical care were available (likely at a price) within the mining community. These can be seen as early attempts at improving conditions, though by modern standards they were minimal.

Health Hazards and Mortality

Despite such provisions, the health toll on Roman miners was enormous. Lung diseases like silicosis from inhaling rock dust were rife; ancient writers observed miners coughing up black phlegm and suffering “short breath” after years underground.

Lead and mercury poisoning silently wrecked the nervous systems of those smelting ores – tremors, madness, and early death would haunt those workers. Many miners bore scars, crushed limbs, or spinal deformities from carrying heavy loads in bent-over tunnels.

The average life expectancy of a mine slave was tragically low; some scholars estimate that a newly arrived slave in the worst mines might last only a few years. The Romans themselves recognized mining as one of the most punishing occupations.

In the eyes of Roman society, to be condemned to the mines was to be effectively erased from the human community – a one-way descent into darkness. Yet, the empire’s demand for resources ensured a steady supply of unfortunate souls to replace the fallen.

The result was an immense human sacrifice largely hidden from the marble forums of Rome: thousands toiled and perished anonymously so that Rome could thrive in the glitter of extracted gold and the iron of conquest.

State Control and Administration

Managing the vast mining operations of the empire required strict administration and a blend of state and private enterprise. In the earlier Republic period, many mines were privately operated under state license. Roman senators and entrepreneurs (often of the equestrian class) would bid for the right to extract resources from a given area, paying the state a share of the profits.

Rise of Imperial Control

As the empire solidified, especially from the time of Emperor Augustus (late 1st century BC) onward, the imperial government increasingly asserted control over mining, particularly for precious metals. Gold and silver were deemed “strategic” resources – the lifeblood of Rome’s currency – and so the emperor often claimed direct ownership of those mines. Many rich mines in Spain, the Balkans, and Asia Minor became imperial property, managed on behalf of the emperor’s treasury (the fiscus).

Procurators and Military Oversight

To oversee these, Rome appointed special officials known as procuratores metallorum (literally “procurators of the mines”). These were usually equestrian-rank officials or trusted imperial freedmen assigned to mining districts. A procurator metallorum acted as a regional director, responsible for production quotas, labor procurement, and the enforcement of laws in mines under their purview.

For instance, Spain’s lucrative mines were divided into zones, each with a procurator to monitor output and send reports (and revenues) back to Rome. In some cases, an entire legion or a part of it might be stationed nearby to provide security and manpower at the procurator’s disposal. The presence of Legio VII Gemina in northwestern Spain, near the gold district, hints that the army was involved in protecting and possibly lending skilled engineers to mining projects there.

Leasing and Regulation

The Roman state also understood the value of private initiative. Rather than micromanage every mine, the administration often leased mining rights to private contractors called conductores. These conductores paid an upfront fee or committed to a percentage of extraction in exchange for operating a mine.

The terms of these leases could be very strict. At the Rio Tinto mines (ancient Urium) in Spain, two bronze tablets from the 2nd century AD (the Vipasca tablets) were found, outlining detailed regulations for a leased mine. They reveal that the mine operators had to pay the imperial authorities half of all ore extracted as a form of tax or royalty – a huge cut, reflecting the value placed on those metals.

The tablets also list rules about mine safety (requiring proper timbering of tunnels), the treatment of slaves (for example, penalties if an owner mistreated slaves so badly it affected output, or if slaves tried to escape), and even provisions for services like taverns and bathhouses in the mining town. The fact that these aspects were regulated shows how organized and bureaucratic Roman mining had become.

Taxation and State Revenue

Taxation and revenue from mining were significant contributors to the imperial budget. Gold and silver especially went directly into coining money – effectively turning ore into imperial pay for legions and public works.

Other minerals like iron and copper might be taxed in-kind (with a portion of the metal delivered to state armories or workshops) or in cash based on their sale. In some provinces, records mention a decuma metallorum, a “tenth of metals” tax, suggesting a 10% tax on privately mined metals. However, for imperial mines, the share was much greater or total.

Emperors such as Hadrian and Marcus Aurelius issued decrees to improve mining efficiency and curb corruption, knowing that any theft or underreporting at mines was a theft from the state. Indeed, the harsh punishments for ore theft described in the Vipasca law (whipping and chaining for slaves, property confiscation for freepersons caught stealing ore) underscore that security of product was paramount.

State-Private Dynamics Across the Empire

The balance between state and private roles varied by region and resource. For example, in Britain’s lead industry, initial direct control gave way to private leasing once the system was up and running – with the caveat that the imperial procurator in Londinium still got that hefty half-share of all lead produced.

In the gold and silver mines of Dacia (modern Romania) after Trajan’s conquest, evidence shows a mix of imperial slaves working under army supervision and leases granted to private Roman companies. Those companies, often owned by senators or knights, operated under imperial oversight and were obliged to deliver a fixed amount of gold to the treasury annually.

Legal Framework and Mine Classification

Roman law also classified mines in legal terms. Many mines on state-owned lands were imperial domanial mines, essentially the emperor’s property. Others on private lands could be worked by the landowner, but even then the state laid claim to a portion of any rich strike (especially gold or silver).

Jurists wrote about mining leases, and special legal titles (metalla) were established for certain mining districts (for instance, parts of Sardinia and Spain had areas legally designated as metalla where normal laws were suspended in favor of mining law).

Bureaucracy in Practice

The robust administration ensured that despite the remoteness of many mines, they were not lawless places. On the contrary, they were tightly monitored economic zones.

One can picture the imperial procurator receiving monthly tallies of extracted ore, doling out rations to the workforce, and arranging transport of the accumulated metal to a secure facility. The soldiers on site acted as both enforcers and police, guarding shipments and deterring rebellion. In effect, some mining zones were akin to military-run industries.

This model of state-private partnership allowed Rome to exploit resources efficiently for centuries. It also meant the Empire could rapidly increase production when needed (for instance, after new conquests like Dacia or during coinage reforms) by injecting more labor or shifting more mines to direct imperial control.

Ultimately, Rome’s management of mining was one of pragmatism. If a local entrepreneur could do the job and fill Rome’s coffers, he was given a contract (with an imperial official watching closely). If a resource was too vital or the profits too tempting, the emperor kept it under his own thumb.

It is telling that during times of crisis (such as the 3rd century AD), when some mines were overrun or lost, the Empire’s fortunes faltered; when the Spanish mines boomed, so did Rome’s reach and building programs. Imperial wealth was, in a real sense, dug from the mines.

Distribution and Trade

Extracting metals and minerals was only half the story – once out of the ground, these resources had to reach the centers of Roman civilization where they would be used. The Romans developed an extensive transportation network by road, river, and sea to move heavy and bulky materials from remote mines to workshops, mints, and markets across the empire.

Roads and Overland Transport

The phrase “all roads lead to Rome” has a literal truth in the context of mining: specially built roads often connected major mining regions to the Roman road network, ensuring the flow of ores and ingots.

For example, in Spain, a route known as the Via de la Plata (“Silver Way”) ran from the mineral-rich northwest (near Asturica Augusta, close to gold mines like Las Médulas) down to Augusta Emerita (Mérida) in the south. Despite its name, this road likely carried gold as well as silver and was a crucial artery for Roman Spain’s mining output.

In Britain, after the conquest, the Romans quickly established roads into Wales and northern England largely to access mines – leading to harbors where metal could be shipped out. The road from the Dolaucothi gold mines in Wales eastward to Isca (Caerleon) is one such example, facilitating the movement of Welsh gold to the coast.

River and Canal Transport

Rivers and canals were the superhighways of heavy transport. Whenever possible, the Romans floated their metals downriver. Rivers like the Guadalquivir in Spain, the Rhône in Gaul, and the Danube in the Balkans carried barges loaded with lead ingots, copper, iron blooms, or even raw ore.

River transport was far cheaper and could handle far greater weight than ox-carts on roads. For instance, lead pigs (ingots) from British mines were transported by cart to the nearest navigable water – perhaps the River Severn or Thames – and then by ship across the Channel to continental markets.

In one telling archaeological find, a Roman lead ingot stamped with the mark of Emperor Vespasian was discovered in a wreck off the coast of Italy, indicating that British lead was being shipped all the way to the heart of the empire. Similarly, Iberian silver bars have been found in hoards in what is now France and Germany, suggesting they were traded or paid out along the northern frontier (likely to pay troops or purchase goods).

Seaborne Shipping and Maritime Routes

Seaborne shipping routes were vital for connecting far-flung mines to Italy and the East. Spanish copper and silver, once refined, were loaded at ports like Carthago Nova or Gades (Cádiz) onto merchant ships bound for Ostia (the port of Rome) or other Mediterranean hubs.

The Romans even branded or tagged their metal cargo: many lead ingots have inscriptions of the mining district, the imperial official in charge, and sometimes the destination. These acted like a form of manifest and quality control. For example, ingots from the Mendips in Britain might read “IMP VESP” (Imperator Vespasianus) and note a weight, underscoring they were imperial property in transit.

The Mediterranean saw a regular flow of metals: iron from the Balkans and Asia Minor to Rome’s armories, copper from Cyprus and Spain to Italian foundries, gold from Dalmatia to the imperial mints, and even marble blocks and millstones (while not metal, still mined products) shipping alongside.

The Minting System

One critical nexus in distribution was the mint system. To turn metal into money, the Romans established mints in key locations. Rome itself (and later Constantinople) was a major mint for gold and silver coinage.

Regional mints existed in cities like Lugdunum (Lyon), Antioch, and Alexandria, among others. When a new haul of gold came from the mines in Dacia, for instance, it might be transported under armed guard directly to the nearest secure mint where it could be struck into aurei (gold coins).

Silver from Spanish or Gallic mines often went to provincial mints to produce denarii or local issues. By coining the metal, the bulky raw material was converted into a far more portable and widely usable form of wealth.

In this way, mining was directly integrated into the monetary economy – one could say the Roman roads carried both the raw metal and then the stamped coins that metal became, in a continuous economic loop.

It was noted that during the heyday of the Spanish silver mines (1st–2nd century AD), Rome could afford vast public works and military expenditures; when those mines declined due to exhaustion or unrest, coinage silver content dropped, inflation rose, and the economy strained.

Private Trade and Local Markets

Beyond official channels, private trade in mined commodities also thrived. Not all iron or tin was monopolized by the state; private smiths and merchants traded these materials in local markets.

A blacksmith in Gaul might buy ingots of Spanish copper brought by a trader, or a workshop in Rome might import Britannic tin to alloy bronze for statues.

Salt, being a lower-value bulk commodity, moved through merchant networks on a local scale – coastal saltworks in Italia would send wagonloads of salt inland to towns, or merchants would carry African salt across the Sahara to Roman outposts.

There was even trade in pigments like the red cinnabar (for vermilion paint) which came from Spain; small quantities were distributed to artists and artisans empire-wide.

Infrastructure and Logistics

The logistics of moving heavy goods required infrastructure. The Romans built and maintained granaries and warehouses (horrea) in port cities not just for grain but also for storing metal ingots and other products awaiting shipment.

Special barges were designed on rivers like the Rhine to haul ore downstream. At ports, cranes and capstans assisted in loading weighty cargo (some lead ingots weighed 70–80 kg each, and a single shipment might contain hundreds of them).

Convoys of ox-carts moved in the mining districts like mule trains, often with armed escorts if the cargo was precious. For the most part, the Pax Romana (Roman peace) ensured that these shipments could travel without interference from bandits or enemy raiders – a critical factor that made long-distance trade in such goods feasible.

An inscription from Gaul thanks the local authorities for repairing a road “used by miners and merchants,” reflecting civic awareness of keeping trade routes open.

Conclusion

In summary, Rome’s mined riches did not sit idle at the pithead. Through a combination of well-kept roads, river barges, and seafaring merchants, the empire orchestrated a circulation of materials.

The end point of these journeys varied: some metal ended up in the state treasuries, some in the form of statues and bronze doors of temples, some as simple tools and nails holding together Roman ships and buildings.

But all of it, whether humble iron or lustrous gold, became part of the fabric of Roman life. The extraction might happen in a barbarian periphery, but the benefits were shared (unequally) across the empire, linking the fate of a miner in Britannia with the prosperity of a forum in Rome.

Environmental and Health Impact

Roman mining was an industrial-scale endeavor carried out in a pre-industrial world, and it left lasting scars on both the landscape and human health. The ecological footprint of the Roman mining industry was probably unmatched until the High Middle Ages or even the Industrial Revolution.

Deforestation and Landscape Degradation

One major impact was deforestation. Smelting metals such as iron, copper, and silver required enormous quantities of wood to convert to charcoal, the fuel for furnaces. Forests around mining regions were heavily logged to keep the smelters going.

Ancient mining zones like the foothills of the Sierra Morena in Spain or the forests of Gaul saw significant tree loss; wood was consumed not only for fuel but also for timber in mine supports and building flumes and structures. Over time, areas near large smelting operations turned to scrub or barren landscapes.

Strabo, the geographer, noted how some formerly wooded areas of Spain had been denuded by mining activity. The removal of vegetation likely led to soil erosion on hillsides, silting up rivers and changing local hydrology.

Water Pollution and Hydrological Changes

Another direct consequence was water pollution and alteration. Techniques like hydraulic mining and hushing at places like Las Médulas fundamentally rearranged watercourses.

Roman engineers diverted streams and drained lakes to supply their mines with water, altering ecosystems. After they left, some of these channels remained, while others broke, causing floods or swampy ground.

Moreover, the process of washing ores released tons of silt, mud, and rock waste into rivers. Downstream of mining sites, riverbeds could become clogged with tailings (mine debris).

Even more concerning, the ore processing introduced toxins: for example, the Rio Tinto (“Red River”) in Spain got its name from the stained, acidic waters colored by iron oxides and sulfates from mining spoils. Roman slag heaps – the waste from smelting – often contained residual lead, arsenic, and other heavy metals that leached into ground and water.

The cumulative effect of many mines across the empire was a widespread dispersal of heavy metals in the environment. Modern scientists have detected a layer of lead pollution in Greenland ice cores corresponding to the Roman era, indicating that atmospheric lead levels during the height of Roman smelting were nearly as high as during the 18th–19th century Industrial Revolution.

That means Roman furnaces pumping smoke skyward in Spain and elsewhere spread a detectable pall of lead across the northern hemisphere.

Impact on Wildlife and Agriculture

Locally, wildlife and agriculture suffered around mines. Pliny the Elder wrote of certain rivers near mines where no fish could survive and nearby soils where plants would not grow, due to contamination.

He also expressed concern (rare for his time) about the “poisonous fumes” released by mercury mining and gold refining. The landscape of Las Médulas, once a natural set of mountains, was transformed into bizarre spires and caves – beautiful in its way, but essentially an artificial badlands created by Roman mining.

Another example is the exhaustion of Spain’s surface gold. By the end of the Roman period, the easily reachable gold was largely gone, leaving later societies with only lesser deposits or much deeper veins to exploit.

Health Effects on Miners and Society

Human health, especially for those involved in mining and metalworking, was severely impacted. Lead poisoning in the Roman world is a well-documented issue – from the elite who sipped wine sweetened with lead syrup to the artisans and slaves who handled lead routinely.

In mining, the exposure was extreme. Smelting galena (lead ore) to get silver released lead vapor that could be inhaled. Miners and furnace workers might develop lead colic (severe abdominal pain from poisoning), neurological damage (leading to tremors or cognitive impairment), and anemia. Skeletal remains of Roman miners sometimes show telltale signs of heavy metal exposure (analysis of bones can reveal high lead content).

Mercury mining was even worse: roasting cinnabar ore releases mercury vapor, which can cause neurological degeneration known historically as “mad hatter’s disease” (trembling, personality changes, hallucinations). It’s likely that slaves in the Almadén mercury mines had very short lifespans, succumbing to mercurial poisoning or lung failure quickly.

Physical Strain and Mortality

Even apart from specific toxins, the physical strain and dangers of mining wrecked bodies. Roman medical texts note lung disease, eye problems (from long hours in dim light), chronic joint pain, and ulcerated skin among mine laborers.

Accidents were common: falling down shafts, being crushed, drowning in sudden floods of water, or suffocating when a tunnel hit a pocket of bad air. There is archaeological evidence of mass graves or disregard for miners’ remains – for instance, at some ancient slag heaps, archaeologists found human bones mixed in, presumably of miners who died and were dumped with the industrial waste. This grim detail highlights that, in many cases, mining populations were considered disposable.

Broader Public Health Concerns

Beyond the mineworkers, urban populations also indirectly faced health impacts. The air in smelting towns was likely thick with smoke containing lead, sulfur, and arsenic.

One can imagine a Roman town downwind of smelters where people frequently had respiratory troubles or where children might show signs of lead exposure (some historians propose that chronic low-level lead poisoning was somewhat common in Roman society due to widespread lead usage).

Limited Protections and Remedies

Romans did attempt some remedies or protections. For example, Pliny recommended that miners suspend a lit lamp or wear a mask of fine cloth over the face in dusty shafts (a primitive respirator idea). Ventilation shafts were a health measure as much as a practical necessity.

Some miners worked in short rotations: Particularly in the most noxious tasks like mercury distillation, probably because it was evident that prolonged exposure was deadly. But these measures were limited and not informed by germ theory or chemistry, only by observation. Ultimately, the drive for resources trumped environmental concern. Any alleviation was primarily to keep operations running, not to preserve nature or health for their own sake.

Long-Term Legacy of Pollution

The legacy of Roman mining pollution outlasted the empire itself. Scientists studying peat bogs in Europe find peaks of lead content in layers dated to Roman times, indicating how far and wide the contamination spread.

The Rio Tinto and other rivers in mining districts remained polluted and biologically dead for centuries. In some cases, medieval people re-entered Roman mines to scavenge remaining ore and remarked on the “bad air” and ruinous state of those ancient works.

It is sobering to realize that the glitter of Roman wealth came at an invisible cost: landscapes permanently altered and a generation of nameless workers sacrificed, as well as subtle harm to the wider population through environmental degradation.

The concept of environmental conservation was virtually unknown to the Romans, nature was to be mastered and used. In their mining exploits, we see that mentality taken to its extreme, with both impressive and devastating results.

Legacy and Archaeology

The remains of Roman mining are among the most striking and informative archaeological sites for understanding ancient technology and economy. Even centuries after the last Roman miner laid down his pick, the landscape bears witness to their labors.

Las Médulas: Hydraulic Mastery

Take Las Médulas in Spain: today a UNESCO World Heritage site, it is a surreal terrain of jagged red peaks and cavernous tunnels amid chestnut forests. What appears as a natural wonder is in fact the residue of Roman hydraulic mining.

Archaeologists studying Las Médulas have mapped dozens of kilometers of Roman aqueduct channels etched into the hills, proving how engineers diverted entire rivers to wash away mountains. In recent years, modern techniques like LiDAR (Light Detection and Ranging) – an aerial scanning method – have been used to penetrate the dense vegetation and reveal the extensive network of ditches, reservoirs, and spoil heaps left from the Roman gold extraction.

LiDAR confirmed that the Roman miners effectively reshaped an entire landscape, creating an enormous mining complex far larger than visible to the naked eye. The success at Las Médulas has spurred similar remote-sensing surveys at other mining sites hidden in forests or remote regions, often exposing the full extent of Roman works that earlier researchers on foot could only glimpse.

Dolaucothi: Gold in Britain

Another remarkable site is the Dolaucothi Gold Mines in Wales, Britain. Long known to locals as ancient “caves,” Dolaucothi was confirmed as a Roman gold mine in the 19th and 20th centuries through finds of Roman tools (like hammers and wooden drainage troughs) and the discovery of coin molds possibly used to melt down gold on site.

Dolaucothi showcases a combination of techniques: there are steep opencast quarry areas where hushing with water stripped the hillsides, as well as several deep adits (horizontal tunnels) driven into the hills, following gold veins. Archaeologists have found the remnants of water tanks and leats (man-made channels) that supplied water for hydraulic mining here.

They even identified the remains of a Roman water-lifting machine at Dolaucothi – likely a series of drainage wheels similar to those in Spain, indicating that even in this far-flung corner, Roman engineers applied advanced solutions. The site today is an open-air museum where visitors can walk through Roman galleries and see pick marks from 1,800 years ago. It is the only known Roman gold mine in Britain, making it a precious window into how the Romans extended their mining expertise to newly conquered lands.

Rio Tinto: Preserved Engineering

The Rio Tinto mining district in Spain (ancient Iberia’s pyrite belt) offers a different kind of legacy. This area saw mining activity from the Bronze Age through Roman times and then a resurgence in the 19th century when industrial companies reopened the mines.

However, the 19th-century engineers often found themselves literally uncovering Roman-era tunnels, tools, and artifacts as they dug. In the early 1900s, miners in Rio Tinto unearthed preserved wooden Roman water wheels in a collapsed shaft, extraordinary finds now displayed in the British Museum and local Spanish museums.

These wheel fragments, preserved by waterlogged conditions, still had notches and even a maker’s mark on them. They confirmed descriptions by classical authors like Vitruvius and showed that Roman mechanical engineering was more sophisticated than previously assumed.

Additionally, Rio Tinto’s acidic waters helped preserve other organic artifacts: miners’ leather shoes, fragments of cloth, and lamps have been recovered, giving a tangible sense of the people who worked there.

Settlements and Documentation

Roman mining archaeology isn’t just about mines themselves, but also the settlements and infrastructure around them. Ruins of mining towns, forts, and workshops have been excavated.

At gold mines in Alburnus Maior (Roșia Montană) in Romania, archaeologists found wax tablets with contracts and letters of the miners – legal documents in Latin from the 2nd century AD, perfectly preserved in collapsed galleries. These tablets recorded everything from a mining company’s formation to a debt acknowledgement, revealing the business side of Roman mining and the presence of a diverse workforce (local Dacians, Roman settlers, even Greeks) living in a mining town with taverns and temples.

In another case, the two Vipasca tablets from Portugal, discovered in the 1800s, were essentially a “notice board” of regulations put up in the mining district – which archaeologists could read to glean how the mine was run.

In some Spanish mines, altars and inscriptions have been found dedicated to mining gods or deities like Mercury (god of trade) and Hercules, showing the spiritual life of miners seeking divine favor for safety and success.

Scientific Advances in Study

Modern science has added new dimensions to studying Roman mining. Geochemical analysis of metal objects (like Roman coins or tools) can trace the signature of the ore, sometimes identifying which mine the metal came from. This has allowed historians to estimate, for instance, how much of Rome’s silver coinage in certain periods was supplied by Spanish versus other mines.

Ice core and sediment analysis (as mentioned) gives evidence of pollution peaks correlating with Roman activity, effectively enabling researchers to chart the rise and fall of mining output through time (a drop in lead around AD 170, for example, might correlate with historical turmoil that disrupted mining).

Mining in Later Periods

The legacy of Roman mining also appears in subsequent eras. When the Western Roman Empire fell in the 5th century AD, many mines in Europe were abandoned or fell into disuse due to instability and loss of technical knowledge.

Some, like the lead mines in Britain, were left untouched for centuries, their tunnels quiet and bats roosting where slaves once toiled. However, in the Eastern Roman (Byzantine) Empire, mining continued in places like the Balkans and Anatolia, carrying forward some Roman methods.

In the medieval period, as demand for metals rose again, people often re-opened Roman mines. They were aided by clues: local folklore sometimes remembered “old workings” and Roman remains. Medieval miners at times simply cleared out Roman shafts and followed them deeper.

They marveled at how well-constructed some ancient tunnels were, and they benefited from the easier pickings the Romans left (for example, a 16th-century account in Spain notes how the locals were still extracting silver from the vast slag heaps left by the Romans, re-smelting them with improved techniques to get the last bits of metal).

Engineering and Cultural Legacy

In terms of engineering heritage, Roman mining techniques were passed down in texts and practice. The writings of Vitruvius and Pliny on mining were copied through the ages, preserving knowledge of things like drainage wheels and prospecting methods.

This knowledge informed miners in the Renaissance when classical texts were rediscovered. The concept of large-scale hydraulic mining, however, was largely forgotten until the modern era (and when it was reinvented in the 19th-century California gold rush, the scale rivaled Las Médulas, causing similar environmental devastation).

Today, archaeologists approach Roman mining sites with a multidisciplinary toolkit. They survey remains on foot, deploy LiDAR and drones for aerial views, do sub-surface geophysics to detect buried shafts, and carefully excavate slag heaps to recover tiny clues like plant pollen (which tells what wood was burnt for charcoal) or metal residues (which tell smelting temperatures and efficiency).

The mining heritage is also increasingly being conserved and presented to the public. Visitors can wander through open Roman galleries at Dolaucothi, or hike the trails at Las Médulas to stand inside the vast man-made caverns. Each tunnel, tool, and inscription paints a vivid picture of an empire that in many ways was as much driven by mining as by military conquest.

Conclusion

In the larger sense, Rome’s mining legacy is the demonstration that a pre-industrial society could achieve an integrated, large-scale extraction economy. It set precedents in law (state ownership of subsoil minerals, for example, which many modern states still assert), in engineering (use of water power in mining), and in the notion that technological mastery over nature’s resources is a marker of civilization.

Of course, it also left a cautionary tale about sustainability: Roman mines boomed and busted, some areas were so thoroughly exploited that they did not recover for millennia.